Location

1242

Contact

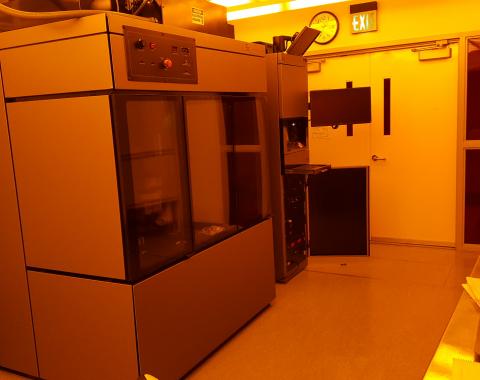

The 5X reduction wafer stepper system is used to shoot a repeating pattern over a wafer. It is capable of resolving sub-micron features as small as 0.6 microns on a 150 mm (6") wafer. Resolution can be pushed beyond this limit with thinner resists. A placement accuracy of +/- 0.15 microns can be achieved with the automated local alignment feature. Pieces (3 mm, 10 mm, 15 mm) up to 150 mm (6") wafers can be stepped via manual loading and custom chucks.

- System: 5X reduction i-line step and repeat, λ = 365 nm.

- Lens system mirrors both X and Y from mask to stepper

- I-line intensity is ~550 mW/cm2 at the wafer.

- Lens: Tropel 2145: 21mm circular field on wafer, NA = 0.45

- Maximum die size ~ 15mm

- Resolution: 0.65um reproducible, 0.55 um achievable R&D

- Registration tolerance: Max 0.25 μm global alignment, Max 0.15 μm, local alignment (with care) < 0.10 μm

- Minimum substrate size: ~ 15 X 15 mm

- Maximum substrate size: > 6 inch wafer (round)

- Automatic Wafer Leveling and Mask Alignment

- The system focus is calibrated daily and registration is checked weekly

- System stages are oiled weekly

- Monthly software backups

- UV Lamp change every 1000 hours

Training Video