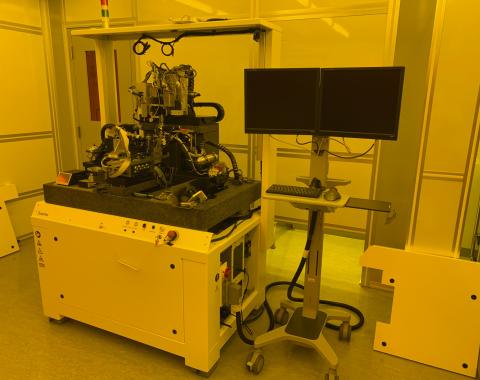

The Ficontec FL300 die bonder is a semi-automatic multi-purpose die/optical component assembly system.

Dies are handled by a pick-up tool. The system captures images by top and bottom cameras, and applies indirect chip-to-chip alignment. Fiber grippers with 6 degree-of-freedom are also available to perform optical coupling. The tool is able to achieve UV epoxy bonding and eutectic/thermal compression bonding.

Tool capability

1. Heater: up to 450 C

2. Force applied from the top pick-up tool: up to 3 N

3. Laser/detector at 1550 nm for optical coupling

4. Two sets of cameras. a) Low-resolution cameras: field ~ 4mm X 4mm, to capture chip edges/corners, deep/through-wafer trenches, and "large" alignment marks (500 um - 2 mm). b)

High-resolution cameras: field ~ 400 um X 400 um, for standard alignment marks (150 um - 300 um